leak rate test for autoclave|bovidic test : agency After the cycle is over, the autoclave’s control panel will show the leak rate in units like psia/min, kPa/min, mbar/min, or mmHg/min. The user’s specifications ultimately determine whether a . Our autoclave indicator labels contain chemical compounds that react to specific sterilization conditions (temperature, time, steam), resulting in a visible and permanent color change from light grey to dark grey at 121°C for 15 minutes.

{plog:ftitle_list}

Autoclaves are designed to harness the power of steam sterilization. The process primarily relies on three key factors: temperature, pressure, and time. Effective sterilization occurs when the steam temperature .

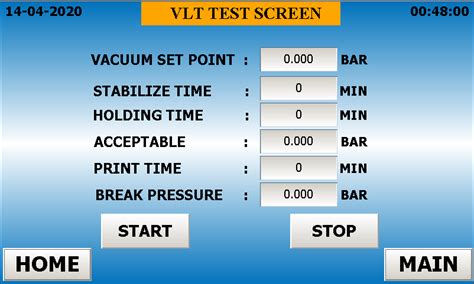

What is a Steam Sterilizer (Autoclave) Leak Test? A vacuum leak test is used to verify the integrity of the sterilizer pressure vessel and its plumbing. Steam sterilizer operator manuals .After the cycle is over, the autoclave’s control panel will show the leak rate in units like psia/min, kPa/min, mbar/min, or mmHg/min. The user’s specifications ultimately determine whether a .At the end of the vacuum test, the autoclave display shows the test result, the batch number, the number of total batches and the determined leak rate. It is important to document this . Vacuum leak test is performed to check any leakage in autoclaves. This test is also called chamber integrity test. . dear sir,is there any calculation to calculate the leak rate for .

After the program was completed, the leak results recorded by the batch were checked. Finally, the 4 leak rates were 1.1, 1.3, 1.5, and 1.7 mbar/min. P5 B-D test program .N o te s : AtypicalLeakTestcyclewilloperateasfollows: StageON E willbetheinitialpull-down. Onceatthepre-setvalue(A),thevacuumpumpwill STOP StageTWO isthefirsttimer .

Built-in leak testing programs usually allow labs to set their own pressure and leak-rate parameters (for reference, in many industries the standard acceptable leak rate is less .

During the test, the autoclave is subjected to a vacuum cycle, and the amount of vacuum lost over a specific period is measured. A typical cycle includes three vacuum pulses, followed by a 15 .In addition to the bowie-dick, leak test autoclave is another important aspect of ensuring the proper functioning of autoclaves. Leak testing methods check the leak during air removal of .The Bowie-Dick tape test or equivalent (AMSCO DART, Lantor cube, Brown’s TST pack) is typically used once a week in an empty chamber to confirm air removal capability. Finally, it is .Vacuum Leak Test for Autoclave: To check for leakage in autoclaves, vacuum leak tests are conducted. “The Chamber Integrity Test” is another name for the Vacuum Leak test. In .

Toverify this, we have to carry out the ‘Chamber vacuum leak rate test . are the responsibility of the autoclave user • For tightness testing purposes, the chamber is pressurized by .An automatic air leakage rate/vacuum test cycle shall be available on sterilizers that utilize a vacuum stage for air removal in any sterilization cycle. If the rate of air leakage into the .And to pass the leak test it needs to be below or equivalent to .1mmhg and can get up to .9 on leak rate. We usually have a guy the worked 20 plus years for steris that now has his own . Vacuum leak test

If the autoclave is sterilizing stoppers for use in aseptic fill and the stoppers are unwrapped (stopper washer processor) then the leak rate test will probably be required on every cycle. .

An autoclave control unit 4 tests operation of the autoclave by turning on a pump 10 to evacuate the pressure vessel 1 and then monitors rise in pressure within the vessel to detect any leaks. . A typical Vacuum Leak Test Cycle will consist of three vacuum/pressure pulses followed by a 15-minute dwell period at deep vacuum. Upon completion of the cycle, a leak .No vacuum device or system can ever be absolutely vacuum-tight and it does not actually need to be. The simple essential is that the leak rate be low enough that the required operating .STERIS has demonstrated through testing, including user testing, that hydrogen peroxide vapor levels surrounding V-PRO Sterilizers are safe and well below OSHA established time weighted .

The different tests are follows for qualification of autoclave are: – Vacuum leak test Bowie-dick test Heat distribution study. . Start the vacuum leak rate test cycle and observe the pressure in . How to Run a Bowie-Dick Test Recommended use of a Bowie-Dick Test is outlined in the Association for the Advancement of Medical Instrumentation's (AAMI) guidance . Return to atmospheric pressure and continue to run for next cycle where vacuum leak rate should not be more than acceptance criteria. Acceptance criteria: Vacuum leak rate .Related: Autoclave Basic Components, Leak Test used in Autoclave, Autoclave Types, biological indicator for autoclave. Important Parameters of an Autoclave. The following factors affect how .

Leak Rate Test Autoclave: Learn the significance of this procedure and discover how it upholds the efficacy of sterilisation processes. Call Us: (02) 8880 7813 Handpiece Repair LEAKAGE TEST: An air leakage test for autoclave chambers is done to find out any leakage from the chamber. Air leakage test is used to establish that the quantity of air .

Page 5 Above the autoclave there must be sufficient space to allow access to the built-in water storage tank (1) and for a good circulation of air. The DAC Professional operates with a blower .

The frequency of leak rate testing (Fig. 1 B) shows that 77% of the pharmaceuticals perform leak rate tests after every commercial batch, 15% execute the test bi-annually, and .

leed ap test hard

vacuum test autoclave

vacuum leak test autoclave

You should not typically fill glass containers beyond 75 per cent of the nominal capacity, as this allows for liquid expansion, and possible foaming, preventing overflow.

leak rate test for autoclave|bovidic test